Yeast reduction of ethyl acetoacetate is an important biocatalytic process used in organic synthesis to produce chiral hydroxy esters. This reaction is widely employed in pharmaceuticals, agrochemicals, and fine chemicals due to its high enantioselectivity and environmental friendliness.This topic explores the mechanism, advantages, applications, and practical considerations of using yeast in the reduction of ethyl acetoacetate.

What is Ethyl Acetoacetate?

Chemical Structure and Properties

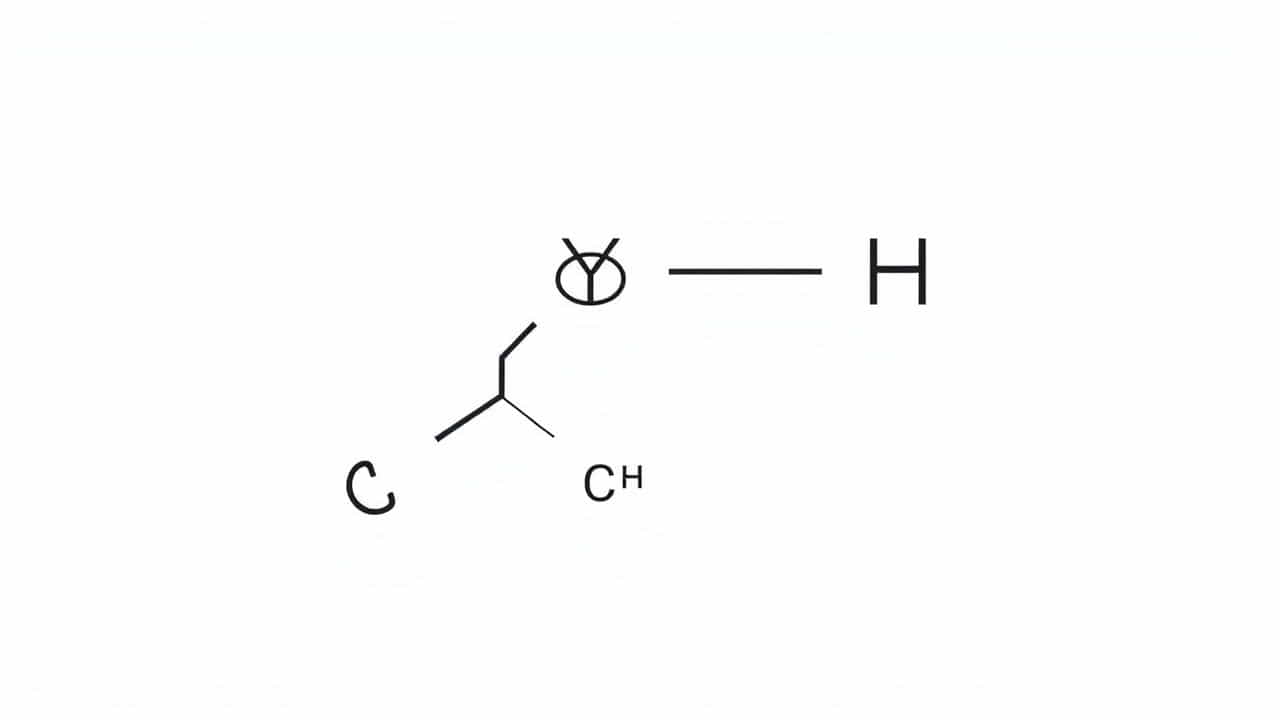

Ethyl acetoacetate (EAA) is a β-keto ester with the molecular formula C6H10O3. It has both ketone and ester functional groups, making it highly reactive in various chemical transformations.

-

Molecular formula: C6H10O3

-

Molecular weight: 130.14 g/mol

-

Boiling point: 180°C

-

Solubility: Partially soluble in water, highly soluble in organic solvents

What is Yeast Reduction?

Yeast reduction refers to the enzymatic conversion of ketones into their corresponding alcohols using yeast cells as a biocatalyst. This process is an example of asymmetric bioreduction, where Saccharomyces cerevisiae (baker’s yeast) is commonly used.

Mechanism of Yeast Reduction of Ethyl Acetoacetate

Step 1: Enzymatic Activation

Yeast contains ketoreductase enzymes, which recognize the keto group (-CO-) in ethyl acetoacetate and catalyze its reduction.

Step 2: Hydrogen Transfer

-

Yeast facilitates the transfer of hydrogen from NADH or NADPH (cofactors) to the keto group.

-

This converts the ketone (-CO-) into a secondary alcohol (-CHOH-), forming ethyl (S)-3-hydroxybutanoate.

Step 3: Enantioselectivity

-

The reaction predominantly yields the (S)-enantiomer of ethyl 3-hydroxybutanoate.

-

The selectivity depends on yeast strain and reaction conditions.

Advantages of Using Yeast for Reduction

1. High Enantioselectivity

- Produces a highly pure (S)-enantiomer, useful in drug synthesis.

2. Environmentally Friendly

- Uses water-based systems, reducing the need for harmful organic solvents.

3. Cost-Effective and Readily Available

- Baker’s yeast is inexpensive and widely available.

4. Mild Reaction Conditions

- Occurs at room temperature and atmospheric pressure, making it energy-efficient.

Factors Affecting the Yeast Reduction of Ethyl Acetoacetate

1. Yeast Strain Selection

Different strains of Saccharomyces cerevisiae have varying enzyme activities, influencing reaction rate and enantioselectivity.

2. Cofactor Regeneration

-

NADH/NADPH is essential for hydrogen transfer.

-

The addition of glucose or ethanol helps regenerate these cofactors, improving efficiency.

3. pH and Temperature

-

Optimal pH: 5.0 – 7.0 (slightly acidic to neutral)

-

Optimal temperature: 25 – 35°C

4. Substrate Concentration

-

Excessive ethyl acetoacetate may inhibit enzyme activity, reducing yield.

-

Ideal concentration is 0.1-0.5 M in reaction medium.

Applications of Yeast Reduction of Ethyl Acetoacetate

1. Pharmaceutical Industry

-

(S)-ethyl 3-hydroxybutanoate is a key intermediate in chiral drug synthesis.

-

Used in the production of antibiotics, anti-inflammatory drugs, and cardiovascular medicines.

2. Agrochemicals

- Important for the synthesis of chiral pesticides and herbicides.

3. Fine Chemicals and Fragrance Industry

- The reduction product is used in making fragrances and flavoring agents.

Comparison of Biocatalysis vs. Chemical Reduction

| Method | Advantages | Disadvantages |

|---|---|---|

| Yeast Reduction | High enantioselectivity, eco-friendly, mild conditions | Slower reaction rate, requires cofactor regeneration |

| Chemical Reduction (e.g., NaBH4, LiAlH4) | Fast reaction, widely available reagents | Low selectivity, hazardous waste, requires strict control |

Challenges and Future Perspectives

1. Improving Reaction Efficiency

-

Research focuses on genetic engineering of yeast to enhance enzyme activity.

-

Use of immobilized yeast cells to enable reusability and scalability.

2. Expanding Substrate Scope

- Scientists are developing yeast strains that can reduce a broader range of keto esters.

3. Industrial-Scale Implementation

- Efforts to integrate biocatalytic reductions into large-scale pharmaceutical manufacturing are ongoing.

Yeast reduction of ethyl acetoacetate is a highly efficient, enantioselective, and eco-friendly process widely used in pharmaceuticals, agrochemicals, and fine chemicals. This method offers mild reaction conditions and high selectivity, making it an excellent alternative to conventional chemical reduction techniques. Further advancements in biotechnology and enzyme engineering will enhance its efficiency and industrial applications.