Understanding Known and Unknown Impurities Key Differences and Their ImpactImpurities are substances that are unwanted or foreign to a product or material. They can affect the quality, safety, and performance of products across various industries, including pharmaceuticals, food, and chemicals. These impurities are often classified as known or unknown, depending on whether they have been identified and understood. This topic explores the differences between known and unknown impurities, their potential risks, and how they are managed.

What Are Known and Unknown Impurities?

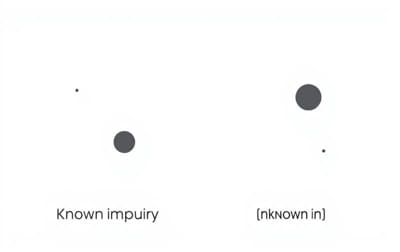

Impurities are substances that are present in a product in small amounts, which can sometimes affect its quality and safety. These impurities can come from raw materials, manufacturing processes, or environmental contamination. Impurities can be broadly categorized into two types known impurities and unknown impurities.

-

Known Impurities These are impurities that are identified, characterized, and understood. Their chemical composition, sources, and potential risks are well-documented.

-

Unknown Impurities As the name suggests, unknown impurities are substances that have not been identified or characterized. They may be the result of unexpected reactions or contamination that was not anticipated during the manufacturing or formulation process.

Known Impurities Identified and Understood

Known impurities are substances that have been previously identified and characterized through scientific research and testing. These impurities are usually well-understood, and their potential impact on the quality of the product is known.

1. Sources of Known Impurities

Known impurities often arise from specific sources, such as

-

Raw Materials Contaminants in the raw materials used in manufacturing processes may introduce known impurities.

-

Manufacturing Processes During production, chemical reactions or the use of solvents can result in known impurities. For example, pharmaceutical products may have residual solvents or byproducts from chemical synthesis.

-

Degradation Products Over time, products can degrade, leading to the formation of impurities that are known to result from this process.

2. Regulatory Standards for Known Impurities

Regulatory agencies, such as the FDA and EMA, set guidelines for the acceptable levels of known impurities in products. These guidelines are based on toxicological data and scientific research to ensure that the levels of impurities present in products do not pose a risk to consumers. Manufacturers must test products to ensure they meet these regulatory limits for known impurities.

3. Managing Known Impurities

Manufacturers take steps to control known impurities by implementing strict quality control measures. These include

-

Analytical Testing Techniques like high-performance liquid chromatography (HPLC) or gas chromatography (GC) are used to detect and quantify known impurities.

-

Process Optimization Manufacturers can modify their processes to reduce the formation of known impurities or to remove them during production.

-

Quality Assurance Regular testing and inspections ensure that known impurity levels remain within acceptable limits.

Unknown Impurities Unidentified and Unpredictable

Unlike known impurities, unknown impurities are substances that have not yet been identified or characterized. These impurities often emerge unexpectedly during manufacturing, and their effects on the product are not well understood.

1. Sources of Unknown Impurities

Unknown impurities may arise from several sources

-

Unanticipated Chemical Reactions New and unforeseen reactions can lead to the formation of unknown impurities during production.

-

Contamination Manufacturing equipment, environmental factors, or human error can introduce contaminants that lead to the formation of unknown impurities.

-

Degradation In some cases, degradation of the product may result in the formation of impurities that were not previously identified.

2. Challenges in Identifying Unknown Impurities

The identification of unknown impurities is a complex process that requires advanced scientific techniques. Manufacturers rely on methods such as

-

Mass Spectrometry (MS) This technique helps detect and identify unknown substances by analyzing their mass and charge.

-

Nuclear Magnetic Resonance (NMR) NMR spectroscopy is another tool used to identify unknown impurities based on the interaction of atomic nuclei with magnetic fields.

-

Chromatographic Techniques Methods like gas chromatography-mass spectrometry (GC-MS) allow for the separation and identification of unknown impurities.

The challenge with unknown impurities is that their presence may not be detected in routine testing, and their potential impact may not be understood until further research is conducted.

3. Regulatory Considerations for Unknown Impurities

Regulatory agencies expect manufacturers to identify and manage unknown impurities. While there may not be specific limits for these impurities, manufacturers are still required to conduct thorough risk assessments and ensure that any potential risks are minimized. If unknown impurities are discovered after a product has been released, manufacturers may need to issue a recall or take corrective actions to protect consumers.

The Importance of Impurity Limits

Both known and unknown impurities can impact the quality and safety of a product. For instance, in the pharmaceutical industry, even trace amounts of impurities can lead to adverse health effects. Therefore, it is critical to set impurity limits to ensure that products are safe for consumers.

1. Ensuring Product Safety

Impurity limits help ensure that products do not contain harmful substances at levels that could pose a risk to health. Known impurities have well-established limits based on scientific research, while the potential risks of unknown impurities are evaluated on a case-by-case basis.

2. Protecting Consumer Health

Excessive levels of impurities, whether known or unknown, can lead to serious health issues. For example, heavy metals such as lead or mercury are toxic even in small amounts, and their presence in products must be strictly controlled. Impurity limits help protect consumer health by ensuring that these substances are present only in safe quantities.

3. Maintaining Product Quality

In addition to health concerns, impurities can affect the quality of a product. In pharmaceuticals, impurities can alter the effectiveness of a drug or cause unwanted side effects. In food products, impurities can affect taste, texture, and shelf life. By controlling impurity levels, manufacturers can ensure that their products meet the desired quality standards.

Managing Known and Unknown Impurities

Manufacturers must take steps to manage both known and unknown impurities in their products. For known impurities, this typically involves

-

Routine Testing and Monitoring Regular testing ensures that known impurities remain within safe limits.

-

Process Optimization and Control Manufacturers can modify production processes to minimize the formation of known impurities.

-

Regulatory Compliance Adhering to industry standards and regulations helps ensure that known impurities are controlled and monitored effectively.

For unknown impurities, manufacturers often rely on

-

Advanced Analytical Techniques These tools help identify and quantify unknown impurities when they arise.

-

Risk Assessments Manufacturers conduct risk assessments to evaluate the potential impact of unknown impurities on product safety.

-

Corrective Actions If unknown impurities are detected, manufacturers may need to recall products, reformulate them, or implement changes in production to address the issue.

Conclusion

Impurities are an unavoidable part of many products, but managing them is crucial for ensuring product safety, quality, and regulatory compliance. Known impurities are well-understood and can be controlled through established processes, while unknown impurities present more challenges due to their unpredictable nature. By understanding the differences between known and unknown impurities, manufacturers can better manage their products, minimize risks, and protect consumers. As technology advances, the ability to detect and control both known and unknown impurities will continue to improve, leading to safer and higher-quality products in the future.